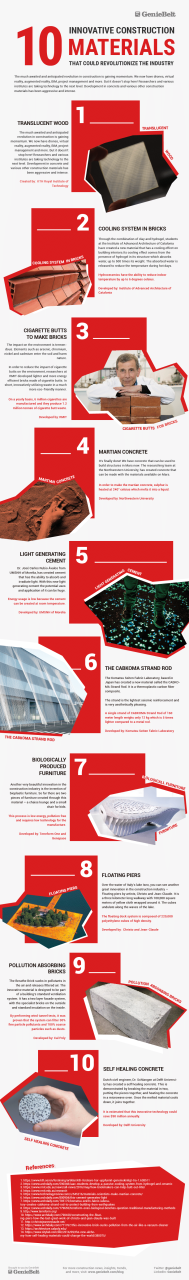

What are the latest modern construction materials?

- Translucent wood

- The cooling system in bricks

- Cigarette butts to make bricks

- Martian concrete

- Light-generating cement

- The CABKOMA strand rod

- Biologically produced furniture

- Floating piers

- Pollution absorbing bricks

- Self-healing concrete

The much awaited and anticipated revolution in construction is gaining momentum. We now have drones, virtual reality, augmented reality, BIM, project management and more. But it doesn’t stop here! Researchers and various institutes are taking technology to the next level. Development in concrete and various other construction materials has been aggressive and intense.

Thanks to that, the construction industry has managed to offer a very convincing answer to the burning question of how modern construction materials could look like in the near future.

Read here: Most common challenges in material management in construction

Let’s have a look at the 10 innovative construction materials that could revolutionize the building sector:

1. Translucent wood as construction material

We now have translucent wood that can be used to develop windows and solar panels. It is created by first, removing the lining in the wood veneer and then through nanoscale tailoring. The resulting effect creates translucent wood that has various application in the construction industry.

As a very cheap resource, it can benefit projects by reducing cost of resource.

The innovation took place at Stockholm’s KTH Royal Institute of Technology. Lars Berglund, a professor at KTH claims that transparent wood is a low cost, readily available and renewable resource.

[Image credits: KTH Royal institute of technology]

[Image credits: KTH Royal institute of technology]

The wood can be mass produced and can be used commercially. The study was then published by Biomacromolecules.

2. Cooling system in bricks

Through the combination of clay and hydrogel, students at the Institute of Advanced Architecture of Catalonia have created a new material that has a cooling effect on building interiors.

Hydroceramics have the ability to reduce the indoor temperature by up to 6 degrees Celsius.

Its cooling effect comes from the presence of hydrogel in its structure which absorbs water, up to 500 times its weight. The absorbed water is released to reduce the temperature during hot days.

Incorporating an innovative cooling system in the current building structure has made Hydroceramics into one of the coolest building materials to revolutionize construction. More progress in this direction, may make household air conditioners obsolete and add one more element on the list of the materials that are needed for building a house.

3. Cigarette butts to make bricks

Many different materials are needed for building a house, but who would expect that cigarette butts will be one of them.

On a yearly basis, 6 million cigarettes are manufactured and they produce 1.2 million tonnes of cigarette butt waste. The impact on the environment is tremendous. Elements such as arsenic, chromium, nickel, and cadmium enter the soil and harm nature.

In order to reduce the impact of cigarette butts on the environment, researchers at RMIT developed lighter and more energy efficient bricks made of cigarette butts. In short, innovatively utilizing waste in a much more eco-friendly manner.

[Image credits: RMIT University]

[Image credits: RMIT University]

Dr. Abbas Mohajerani, the leading researcher of the project, along with his team discovered that by infusing even 1% of cigarette waste in fired-clay bricks they can have great results in removing pollution from our environment.

Not only does this research help with reducing waste, but the resulting brick is also lighter and requires less energy in manufacturing it.

So next time you will wonder what materials are needed for building a house, make sure that you don’t underestimate the power that a small object such as a cigarette might have.

4. We now have Martian concrete

It’s finally done! We have concrete that can be used to build structures in Mars now. The researching team at the Northwestern University, has created concrete that can be made with the materials available on Mars.

The new concrete also doesn’t require water as an ingredient to be formed. With the scarcity of water as a source, this crucial benefit can make this innovation truly beneficial for the development of structures on Mars.

In order to make the martian concrete, sulphur is heated at 240° celsius which melts it into a liquid. The martian soil then acts as an aggregate and once it cools down we get Martian concrete! According to the researching team, the ratio of martian soil and sulphur needs to be 1:1.

5. Light-generating cement

Dr. José Carlos Rubio Ávalos from UMSNH of Morelia, has created cement that has the ability to absorb and irradiate light. With this new light generating cement the potential uses and application of it can be huge.

The construction industry is evolving and one of the main trends is the move towards a more resource and energy efficient way of creating structures. Therefore, the implications of cement acting as a ‘light bulb’ are very broad. We can use them in swimming pools, parking lots, road safety signs and much much more.

Read also: Construction technology startups set to transform the industry

The science behind it: Through the process of polycondensation of raw materials such as river sand, industrial waste, silica, water, and alkali. The process is done at room temperature which is why the energy usage is low.

In short, we now have smart cement!

6. The CABKOMA strand rod

The Komatsu Seiten Fabric Laboratory, based in Japan has created a new material called the CABKOMA Strand Rod. It is a thermoplastic carbon fiber composite.

The strand is the lightest seismic reinforcement and is very aesthetically pleasing.

A single strand of CABKOMA Strand Rod of 160 meter length weighs only 12 kg which is 5 times lighter compared to a metal rod.

The value of this material can be seen at the headquarters of Komatsu Seiten. The strands have enforced the entire structure.

7. Biologically produced furniture

Another very beautiful innovation in the construction industry is the invention of bioplastic furniture. This innovation is due to the joint effort of Terreform One and Genspace.

So far there are two pieces of furniture created through this material – a chaise lounge and a small chair for kids. The furniture is made by a material called Mycoform, which is made by combining wood chips, gypsum, oat bran together with a fungus called Ganoderma lucidum. This fungus is added as it has the ability to disintegrate waste products and leave a strong structural material.

[Image credits: Terreform One]

[Image credits: Terreform One]

This combined effect creates plastic furniture that through time combusts. According to Terreform One, this process is low energy, pollution free and requires low technology for the creation.

8. Floating piers

Over the water of Italy’s lake Iseo, you can see another great innovation in the construction industry – Floating piers by artists, Christo and Jean-Claude.

The floating dock system is composed of 220,000 polyethylene cubes of high density. It is a three-kilometer long walkway with 100,000 square meters of yellow cloth wrapped around it. The cubes undulate along the waves of the lake.

The beautiful masterpiece extends from pedestrian streets of Sulzano and connects the islands of San Paolo and Monte Isola.

9. Pollution absorbing bricks

We now have pollution vacuums in bricks! Developed by assistant professor Carmen Trudell at Cal Poly, college of architecture and environmental design, the Breathe Brick sucks in pollutants in the air and releases filtered air.

The innovative material is designed to be part of a building’s standard ventilation system. It has a two-layer facade system, with the specialist bricks on the outside and standard insulation on the inside.

Check out also: How digital technology is changing the construction industry

In the center is a cyclone filtration system that separates out the heavy air particles from the air and collects them in a removable hopper. Its design is very similar to a vacuum. The design of breathing bricks can be configured in a wall with a window and a cooling system as well. In short, it is a technology that can be easily applied to the current construction processes.

By performing wind tunnel tests, it was proven that the system can filter 30% fine particle pollutants and 100% coarse particles such as dust.

It goes without saying that pollution absorbing bricks could become in the long run one of the most common materials needed for building a house as they would ensure a better quality of life for the residents of the built structure.

10. Self-healing concrete

Self-healing concrete is also a new entry in the family of the materials used in construction and we are really excited about it!

Dutch civil engineer, Dr. Schlangen at Delft University has created a self-healing concrete. In his presentation, he demonstrated the effectiveness of the material by breaking it in two, putting the pieces together, and heating the concrete in a microwave oven. Once the melted material cools down, it joins together.

Of course with this method, the concrete needs heat. If the material is used to create roads, how will they be heated up?? To solve that problem, Dr. Schlagen and his team created a special vehicle that passes induction coils on the road.

Dr. Schlagen estimates that the machine will be used to run on the concrete every four years and that this innovative technology could save the country $90 million annually.

What’s next for traditional building materials?

By now, it’s evident that the construction industry is about to enter a new era in terms of construction materials. Of course, this has a direct effect on traditional materials and their role in the building process.

There are two different scenarios for the use of traditional construction materials in the -not so distant- future: they will either perish due to the use of new revolutionary techniques or they will be reiterated in order to become a profitable and eco-friendly option which complies with the modern building specifications and standards.

Interestingly enough, traditional building materials have lately attracted a lot of attention as a result of the search for new ways to turn construction greener and more cost-efficient. In a nutshell, here are some of the materials used in construction that belong to this category:

- Earth building materials

- Wood as a building material

- Bricks

- Concrete

- Cement

- Plastic

All the materials mentioned above could contribute to transforming the way we build in the sector if used in a smart and sustainable way. On top of that, they could play a decisive role in decreasing the cost of materials in the construction process without compromising quality.

The future looks promising!

All in all, it becomes clear that many things are already changing in the sector with regard to the materials used in construction. The potential is enormous and as long as we are able to combine the traditional building materials with a modern approach then a more cost and energy-efficient building process will emerge soon.

[

[