Nicholas Klokholm, Director of Channel – Volume Builders at LetsBuild, shares with us his thoughts on why construction should become more data-driven in order to ensure future success:

Are we focussing on the right things in our industry at the moment or have we fallen for the “nice and shiny” instead of looking at what is actually broken?

Everybody is talking about BIM, AI, AR etc. but is the implementation of any of those technologies really the best first step to take in order to truly digitize our industry?

We are talking about technologies that require a lot of data and structured processes in order to get the full benefit from them.

Let us take a step back before I give my point of view on this question.

The reason why we want to use BIM is to have a place to store and share the information needed on a project so that we ensure that we have the right tendering process with the precise amount and kind of materials to be used a design that is agreed and accepted by the parties involved. The next step is of course to have a common ground of how the building should look when we build it, and later for the owner to have the FM information needed to service it for the next +50 years.

So we want BIM because we want a common ground to work from. In other words, it is about collaboration and sharing of data.

And that takes me to my next point… Do we generally think that the way we collaborate today is working for us? I attended a Contech conference a few days ago where the major players in a panel discussion all talked about the fragmentation in our industry (so If I should translate it, it would say that the collaboration does not work currently).

Over the last couple of years I have talked to hundreds of people in our industry at all levels from C-level to workers on-site and what I hear every time is that we need better collaboration but at the same time are all too afraid of transparency to actually create a common ground for collaboration because of the way we work today.

So, we keep on supporting our current way of working instead of taking a step back and saying “nobody wins with the way we work”. The key is to dare to show that none of us is perfect and yes, we all make mistakes but if we raise the flag as soon as problems occur, we can actually solve them with all brains in the game instead of waiting so long that it is costly for everyone to fix them.

So we are supporting the old way of working due to bad habits and because we are afraid that the person next to us is not as honest as we are. That is where transparency comes into the picture – a lie can only hold out for so long if the truth can be found in transparent information.

Compare it to your private life – would you accept to only align once a week with our partner and to not get the full truth every time?

So to get back to BIM… BIM is about processes and facilitating data. But if we do not have the processes in place, the use of BIM will not meet its full potential. And if we do not start using data as the main driver in our industry, we will keep going without a good learning loop and repeating the same mistakes over and over again.

We need to embrace the technology that can actually help us get our processes in place and start collecting data if we want to be ahead of the competition.

And I am not talking about stand-alone solutions but solutions connected to each other as one platform. To give an example:

The BIM model contains the information needed in the document & drawings system. The same information is needed in the snagging/quality/checklist tool, and both of these are reliant on the actual task on-site. Each task needs to be connected to both systems as we want to assign the worker on-site his or her tasks, but it should be easy for the worker to find the right drawings or location of the installation.

Read also: Data culture – The missing link in construction

Once a task has been completed and progress has been reported, the worker should automatically receive a quality inspection checklist. In other words, no matter if the information comes from 3 or 30 different platforms, for the people using it, it should feel like a smooth flow. Every bit of information needed for different processes should float between systems to optimize the user experience. We are only humans and we will always think “what is in it for me” before adopting technologies.

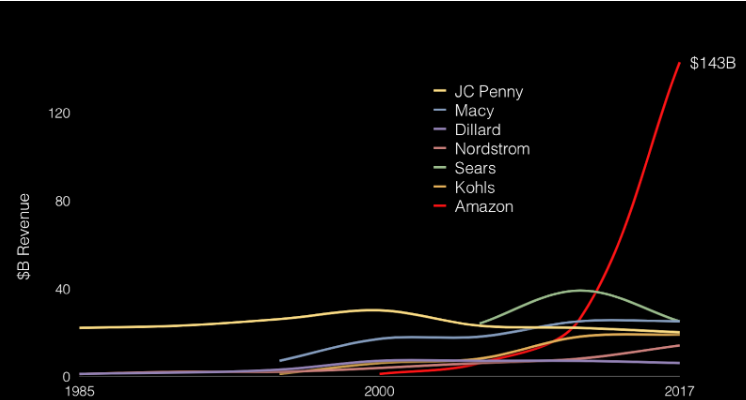

For the past few years, we have been joking that Amazon, Google and the like might come and disrupt our industry… This is no longer a joke!!! They are here and they are hungry. Amazon just invested in the start-up Plant Prefab. Amazon and the rest of the big 5 have the firepower to hire the best people in our industry and make sure that everything there works from the perspective of data. Because that is the way they disrupted other industries.

To remain competitive and to be fit for the future, the construction sector needs to embrace data driven technologies.

More than 18 years ago, Amazon had the data to recommend people which books to buy that matched their taste (60 Minutes interview “Nerd of the Amazon”).

I have asked several of the largest players in our industry if they have the data to show how much time they have spent installing 10m2 of type X on their last 3 projects.

Everyone, including those who work with VDC, had the same answer: We do not have the numbers but we know approximately how long it takes and hence how much it costs. But if that is the case, then how come 80% of all projects go over time and budget?

This is where the right technologies and processes can provide real value.

A lot of the processes in construction are repetitive, even if the projects seen from the outside are different. If we start collecting all the data available on a project and use BIM as the central data hub, we can get to a point where we start learning from one project to another.

Whenever we use object X in a BIM model, machine learning can start telling us what else we need in order to get the model to a level that can be used later on – a buildable model. And using experience data from previous projects, objects can be enriched with the 4th Dimension (time) so we get better at forecasting and planning our project. The 5th Dimension, budget, needs a whole new level of structure so let’s keep that for another blog post.

I recently attended a conference held by materials supplier Solar. They had invited a futurist (a trend researcher) who said some very inspiring things about new technology.

As the name says it is “new” so it is not perfect yet, but it can still help us disrupt our way of working for the better. But in our industry, we are terrified of doing things in a different way from the way we are used to. Low margins – which are typical in construction – also mean risk averseness.

But if we do not invest in technology and change management, we will end up like Sears and other old-world retailers.

Have a look at the curve below:

Traditional retailers that do not use modern technology to disrupt the industry and even – as in Amazon’s case – take over parts of the value chain, stagnate or die. If we don’t want to end up like Sears, however, we should accept that there is a cost to improvement in the short term. The end goal is worth it, though!

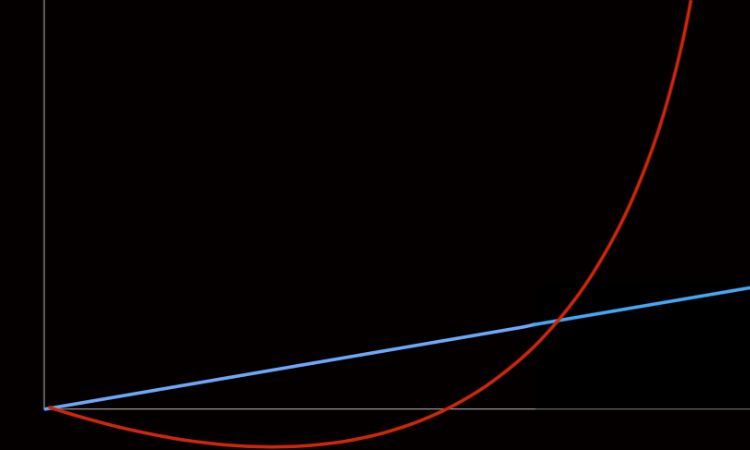

Take a look at the blue curve below. It shows that if we do just improve a little bit every day (LEAN, daily update meetings etc.), at some point the curve will go down as the business is disrupted by something/someone else. The red curve, however, is where you want to be.

But that requires management and/or board to accept that the change will cost some money (in the short term). However, it will eventually transform the business to be state-of-the-art, outperforming any incremental approach, doing what we do today a little bit better.

If I have to provide my vision of what is behind the red curve, it would be working with transparency, data, machine learning, VDC, drones, sensors, but all of them in a connected manner to get full transparency and the overview needed to be able to make the right decisions at any given time.

Too many companies start with the “nice and shiny” solutions rather than understanding what is critically important for the people on site every day and beginning to solve that! The efficiency rate for construction workers on site is only 30%, to a large extent due to lack of information and poor communication to the people that need to do their jobs. So, there is plenty of money to harvest without compromising profit.

In an article, McKinsey recently described digitalization in general and the problems faced by the industry very well:

“Many senior executives aren’t fully fluent in what digital is, much less up to speed on the ways it can change how their businesses operate or the competitive context. That’s problematic. Executives who aren’t conversant with digital are much more likely to fall prey to the “shiny object” syndrome: investing in cool digital technologies (which might only be relevant for other businesses) without a clear understanding of how they will generate value in the executives’ own business models.

They also are more likely to make fragmented, overlapping, or subscale digital investments; to pursue initiatives in the wrong order; or to skip foundational moves that would enable more advanced ones to pan out. Finally, this lack of grounding slows down the rate at which a business deploys new digital technologies. In an era of powerful first-mover advantages, winners routinely lead the pack in leveraging cutting-edge digital technologies at scale to pull further ahead. Having only a remedial understanding of trends and technologies has become dangerous.”

So, to sum up, my best advice for our industry is:

STOP looking for tools and start looking at broken processes and links and how to solve that.

Then you know your biggest pains and you are able to find a suitable solution for them.

Get your current data highway up and running while embracing transparency and dare to show vulnerability to bring trust back into our industry. Recognise that this is not something you can solve alone in your company, but you can start embracing it and people will follow!

In order for our industry to change we need to change our behaviour and we need to start embracing and collecting data as a way to improve, just like banking, manufacturing and a lot of other industries have done in order to keep up with the competition.

WE ARE READY to connect construction! ARE YOU?