This is something I’m not at all sure of because they didn’t have the advantage of me to sort it out for them. I was free-lancing and this was a nice long-running project, but nobody ever offered me a job on it! Still, I wasn’t that upset really; didn’t fancy being stuck underground under the sea!

The usual thing with construction projects! They started talking about it in 1802 but didn’t start building it until 1988! Then it opened up just 6 years later in 1994. The original budget for the job was £2.65 billion but it ran over by 80% and ended up at £4.65 billion.

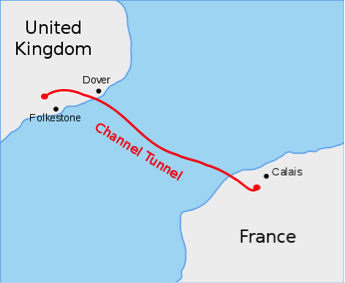

It starts off near Dover and runs for 32 miles under the English Channel, resurfacing at Coquelles, near Calais in France – or the other way round if you prefer!

By Mortadelo2005 (en:Image:Course Channeltunnel en.png, by Weyoune) [GFDL, CC-BY-SA-3.0 or CC BY 2.5], via Wikimedia Commons

By Mortadelo2005 (en:Image:Course Channeltunnel en.png, by Weyoune) [GFDL, CC-BY-SA-3.0 or CC BY 2.5], via Wikimedia Commons

We’ll forget all the geological surveys that were done. Not something that interests us in construction. We just do whatever they eventually decide we have to do! All we really need to be aware of is that water ingress from the sea above was a consideration for depth and direction.

I do seem to remember that a 2 inch diameter hole was drilled, staring at both ends, and actually meeting in the middle! They then started excavating the main tunnels. This was very much experimental because no such tunnel had ever previously been made. The idea was a smaller service tunnel down the middle with a much larger one for the trains down each side. These were to be linked at intervals with tunnels to the rail tunnels and also smaller piston relief ducts to equalise the pressure as the trains bombed along the track.

The two rail tunnels are 7.6-metre-diameter (25 ft.) and 30 metres (98 ft.) apart. The service tunnel is 4.8-metre diameter (16 ft.). The pairs of 3.3-metre diameter (11 ft.) cross-passages linking the rail tunnels to the service one are 375-metre (1,230 ft.) intervals. The relief ducts are 2 metres (7 ft.) in diameter and are 250 metres (820 ft.) apart.

So off they set from both ends. The service tunnel was always a kilometer ahead of the rail tunnels to ascertain the ground conditions. Six Tunnel Boring Machines (TBM’s) set off from the French side and six of them from the English side. Having dug a bit of tunnel it then had to be lined.

Find also: How they built the Hoover Dam

Precast segmental linings in the main TBM drives were used, but two different solutions were used. On the French side, neoprene and grout sealed bolted linings made of cast iron or high-strength reinforced concrete were used; on the English side, the main requirement was for speed so bolting of cast-iron lining segments was only carried out in areas of poor geology. In the UK rail tunnels, eight lining segments plus a key segment were used; in the French side, five segments plus a key.

When they were done the UK TBMs were driven steeply downwards and buried clear of the tunnel. These buried TBMs were then used to provide an electrical earth. The French TBMs then completed the tunnel and were dismantled.

After that it was pretty simple in that it had all been done before; railway lines got laid! Well they also had to run tracks to and from the tunnels and the railway stations to service them, but again, pretty simple!

It might have been a costly project but a very useful one! In 2014 Eurostar carried 21 million passengers and 20 million tons of freight!

If you liked this post, then you will love reading about how they built the Eiffel tower!